TMVSS Veterinary

TMVSS Veterinary description v4.0-1.2.2023

A powerful tool for the tested process is fully automated and non-invasive data collection, which in no way restricts the evaluated animals and takes place automatically without the need for maintenance. The used thermographic measurement takes place after the automatic reading of the piece by RF-ID identifier when the cows pass around the camera, without this online measurement disrupting the animal's movement or causing him pain or any stress. The purpose of this technical tool is to replace the work of the breeder and the use of everyday, often even multiple automatic tracking of individual pieces. For accurate identification of dairy cows, therefore, the identification that farms have at their disposal for the identification of cows in the milking parlor or in feeding boxes.

The system used in its evaluation algorithm takes into account the fact that individual animals, like all living organisms , temporal and physiological variability. For this reason, an element of group, individual, but also time differences was entered into the algorithm for evaluating individual monitored quantities. For this reason, it is not possible to be satisfied with the state used so far, where individual pieces are evaluated due to the complexity and overall variability to the population average, which is usually considered as a steady state system. Three conditions must be met to successfully set up evaluation processes.

The first condition that must be met is that the individual evaluated factors of animals must be measured continuously, respectively. as often as possible. This is ensured, for example, by a daily passage around the thermographic camera at each entrance to the milking parlor.

The second condition deals with the performed data analysis. The result, which warns of a change in health status, cannot be expected and must be available to the breeder within a few minutes. The result on the change in health status is the content of the press report, or information for separation gates and urgent treatment of individual animals. These may be diseases such as dermatitis, necrobacillosis or hoof inflammation which are preceded by symptoms of inflammation before the onset of pain, such as locally fever, redness, swelling and dysfunction. Early diagnosis of this altered health condition will allow effective intervention in the preclinical phase and management of the whole situation without impact on performance, with low treatment costs and overall disease prevention.

Thus, a system functioning in this way is, by its nature, one of the preventive measures in the daily struggle with limb disease, which on many farms exceeds ten and in some cases even tens of percent.

The third condition for the effective application of the entire thermographic system of limb health assessment is a multidisciplinary biological-technical approach with fully automated collection of defined data and their online evaluation. All measured data are stored and in addition to the detection of limb diseases, which are accompanied by locally elevated temperature, they provide a tool for evaluating the effectiveness of treatment of individual diseases based on the course of measured temperature variables on the affected limbs. In this context, it should be mentioned that limb temperature appears relatively individually for each individual. Therefore, a simple criterion cannot be used, such as a temperature less than 28 degrees. Celsius is fine, while everything over 28 st. indicates a problem (specific temperature values were given as an example)

Automation of all processes is a way to not only make the whole process significantly more efficient, but especially to make it significantly more sensitive to the first symptoms of developing deviations. If we look at the current practice (if thermodiagnostics is introduced at all), the measurement is performed by an authorized employee only a few times a month, which prevents early detection of the first symptoms of the disease, is time consuming and telling ability is greatly influenced by the authorized employee. Likewise, occasional measurements cannot take into account fluctuations caused, for example, by limb contamination.

Automation, on the other hand, brings several key aspects for successful monitoring of developing disease symptoms:

- Uniformity of assessment, including setting of limit values for states

- Frequency of measurements up to several times a day

- Time-saving in terms of operation

- Possibility to control selection elements

- Data archiving and long-term evaluation of trends

- Significantly more cost-effective compared to „manual measurements“ or measurements requiring the animal to be placed in a fixation cage

- Reliability versus simple assemblies based on absolute temperature limits, or requiring manual data evaluation

If we look at the individual aspects in more detail, we can characterize them as follows:

Uniformity of assessment - if thermodiagnostics is performed by an authorized employee, we always depend on his knowledge level and ability to routinely control both the camera and evaluate thermograms (measurement records). In contrast, the automated system uses a consistent algorithm with the ability to set multilevel thresholds. It is therefore possible to easily generate reports with an overview of the current locomotor score, as well as to compare the measured values between individual herds and breeds. The value of the „LS“ index is always automatically determined for the individual pieces after the passage. This index is calculated on the basis of specific temperature characteristics of the limbs and roughly corresponds to the indices of the „locomotion score“, but it is a different type of assessment, although the measured index „LS“ roughly corresponds to the value of the „locomotor score“. A great advantage over the current practice is that if the locomotor score is evaluated in the usual way, the seizures start around the value of 3, ie when the individual has visible problems with movement and posture. In contrast, using thermographic measurements, we indicate the „LS“ index across the entire value scale (1-5) and we are able to detect limb disease at an early stage, when it does not yet cause movement difficulties. Examples of detection will be given in the final part of the material.

Measurement frequency - an automated system measures each piece passing through a marked corridor, for example at the entrance to a milking parlor. In real operation, this means (if both entrances to the milking parlor are equipped with cameras, for example) that each piece is measured several times a day. This enables both the detection of initial deviations in the state of health and the verification of detection, or monitoring of the dynamics of the disease or the effectiveness of the set and applied treatment. Likewise, automated data processing makes it easy to create trends or advanced analyzes of disease causes.

Time-saving - an automated system is easy to operate and all the operator needs is to clean the camera system with water in case of contamination excrement. This applies, of course, if the camera is mounted in a waterproof housing. The output is a table with a list of individual animals that are suspicious with their categorization according to the locomotor score. If the authorized operator, usually a zootechnician, wants to analyze the data in more depth, he can of course do so conveniently, as the individual records are automatically assigned to specific animals.

Possibility to control selection elements in real time, the monitoring system enables automatic separation of suspicious animals through a selection gate and thus allows the zootechnician or veterinarian to verify the monitoring findings.

Data archiving and long-term evaluation of trends - today's emphasis is not only on monitoring the current state, but also preventive measures to prevent the development of the disease. This generates a clear requirement for retrospective, long-term and detailed analysis of the performed measurements, or searching for connections with external influences. In practice, this is very difficult if only the walk measurement is performed by an authorized worker. It is not feasible for a zootechnician to analyze hundreds of thermograms at regular intervals, assign them to specific animals and enter them manually into a system for later analysis.

Financial efficiency - if we compare the primary investment costs between an automated and, above all, functional system, and a mid-range portable thermal imager, the automated system will emerge as a seemingly more demanding solution. However, this is an apparent financial difference, which is in fact in the opposite direction. The cost component also includes variable costs, such as operator training, employee time required to perform measurements, but mainly evaluation. If the given process is to be carried out really responsibly with the help of a „handheld thermal camera“, in reality it is a matter of tens of hours a week, which will significantly affect the economic balance of wage costs per authorized worker. At the same time, the question is whether the authorized worker (zootechnician) is able to devote several tens of hours per month to this activity, as he is usually very busy. At the same time, it is necessary to take into account the reduction of the capture efficiency of individuals due to the significantly lower frequency of measurements (compared to a fully automated system), as well as the decrease in the telling ability in the case of measurement and evaluation by multiple workers. In general, it can be assumed that, including all costs, the economic balance will level off within 9-15 months of the investment, while the explanatory power of a fully automated system is significantly higher.

Reliability compared to simple assemblies - In practice, we can meet with designs of seemingly automated solutions, either based on the permissible temperature limit (eg tmax> 250C) triggering the recording, or on solutions that trigger the recording of images with each pass of the dairy cow and store them. In the first case (permissible temperature limit), the method does not allow the setting of sufficient sensitivity due to the natural difference in limb temperatures between individual healthy pieces and the oscillation of these values depending on the time of day and season. This difference can be up to 100C in healthy individuals, so this procedure leads to either a significant number of false alarms or its insensitivity. The second approach (simply recording thermograms with each pass) in practice means that the zootechnician will spend hours evaluating the thermograms, which introduces not only the aspect of time / money, but also inconsistency in the assessment of individual findings. Such pseudo-automatic solutions only lead to disappointment of users and, in addition to their financial demands in terms of high variable costs, show a high degree of uncertainty and thus real inapplicability.

Therefore, if we make a comparison between the effectiveness of an advanced automated solution and a „portable“ solution, both in financial and performance terms, then both criteria speak clearly in favor of an automated solution - in the case of explanatory power in favor of an automated solution immediately, from an economic point of view. in the order of several months with increasing economic advantage over this time horizon due to practically zero variable operating costs. If necessary, the authors are ready to prepare an individual calculation of economic parameters for individual farms.

Application examples:

Dermatitis

On The following graph shows the development of the „LS“ index on individual days: the individual points indicate the calculated value and its comparison with the limit values for levels 1, 2, and 3.

The trend of the index is clearly visible on the chart, when 31.10. the first exceedance of the LS1 level can be seen. the trend is clearly increasing until the moment of treatment on 2.11., when the indication of the deployed automated system was confirmed within the treatment of the hoof with the finding in the picture. After treatment, it can be seen that the detected „LS index“ showed a significant improvement (well below the LS1 limit). however, it is re-growing, i.e. apparently suitable for re-treatment. In this context, it should be noted that the affected piece did not show visible signs of movement problems. It is also worth noting the time dynamics of the development of the index - ie in the order of days.

Necrobacillosis

The following graph shows the evolution of the „LS“ index on each day: the individual points indicate the calculated value and its comparison with the cut-off values for grades 1, 2, and 3:

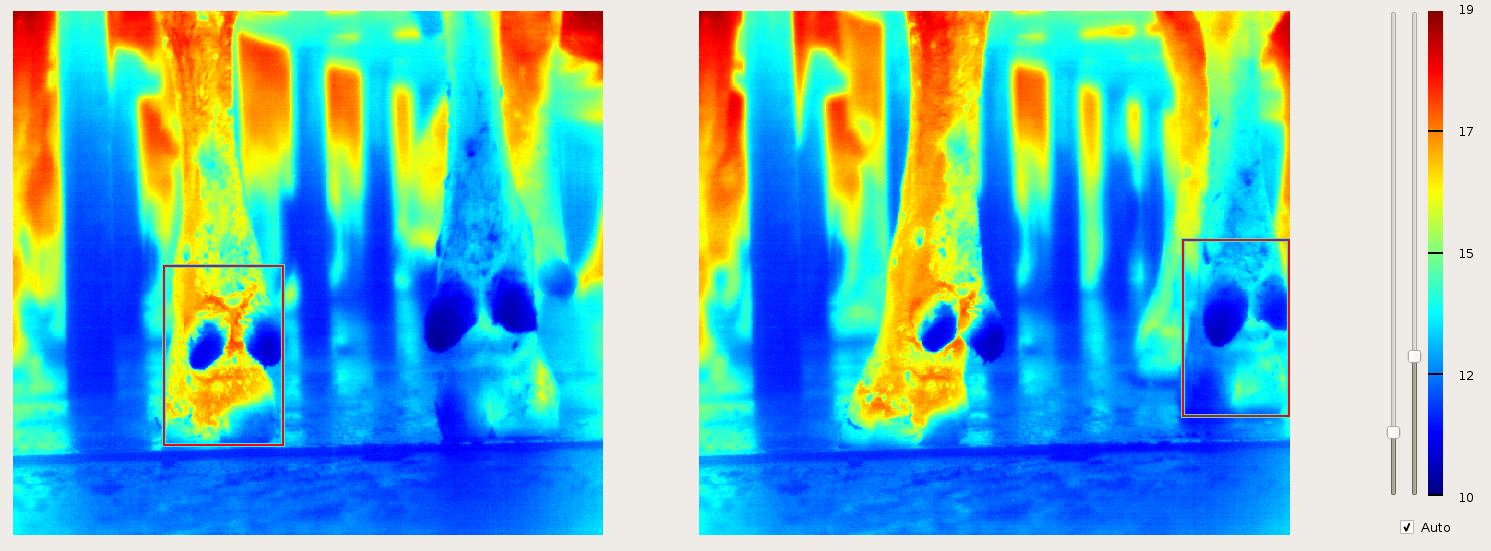

The first signs around 29.10 can be observed on the graph. which are confirmed by the trend in the following days (can be used as an example of why it is necessary to perform measurements continuously and monitor the development of values, not just isolated values) until treatment 2.11. with the following finding:

It can be seen from the photo documentation that although the necrobacillosis lesion was not visible in normal operation, it was a completely demonstrable lesion, as can be seen in the picture showing the hoof after treatment. The above chart also shows a very good improvement in the „LS“ index.

These examples clearly document the possibility of catching sick individuals at the beginning of the development of the disease, which in turn results in more effective treatment options and better access to individual pieces.

It should be emphasized that this is an advanced automated system, ie a complete unit, the output of which are reports with a generated evaluation of the locomotor score and the development of specific temperature indicators. A solution where manual evaluation of thermograms by the operator, zootechnician or a seemingly effective solution of exceeding the limit temperature on the limb cannot be considered an automated system.